We know that the construction, installation, maintenance, and defect elimination of petrochemical projects require the dismantling and pre tightening of a large number of equipment flange bolts. On site tools such as hydraulic wrenches, lithium-ion torque wrenches, electric torque wrenches, manual torque wrenches, hydraulic bolt tensioners, and hydraulic separators are essential. But how to configure it still needs to be combined with the on-site working conditions. A petrochemical customer inquired about on-site inspection and maintenance tool solutions. On site hydraulic wrenches are definitely needed, but customers are hesitant about which one to choose between electric torque wrenches and lithium-ion torque wrenches. This issue is definitely a concern for many customers, so today we will discuss these two types of torque wrenches.

There is not much difference in speed between electric torque wrenches and lithium-ion torque wrenches, so when choosing, one can only compare which one is more suitable in terms of accuracy and usage.

In terms of accuracy, electric torque wrenches usually have high precision, and the standard precision of electric torque wrenches used in the general chemical industry is ± 5% torque accuracy. It can effectively ensure efficient pre tightening speed and pre tightening effect. If a higher precision electric torque wrench is selected, speed needs to be sacrificed for accuracy. The design accuracy of lithium-ion torque wrenches is within ± 3%, which is obviously higher than that of electric torque wrenches. Due to the use of battery power, the lithium torque wrench has a smoother torque output, resulting in better pre tightening effect during assembly.

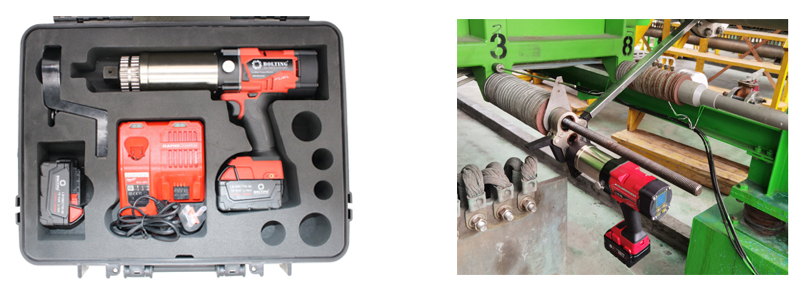

From a usage perspective, electric torque wrenches require connection to a power source to function, thus limiting their range of use. However, they typically have a large torque output range and are suitable for various bolt specifications. Lithium ion torque wrenches do not require an external power source, making them more flexible and convenient to use. They are usually compact in size, lightweight, and easy to carry. However, the torque output range of lithium-ion torque wrenches is relatively small, making them suitable for assembling small and medium-sized bolts.

Overall, lithium torque wrenches have good performance in both accuracy and usage. At the petrochemical site, precise assembly of small and medium-sized bolts is required, which requires efficiency and more flexible operation. Undoubtedly, lithium torque wrenches are a more suitable choice.